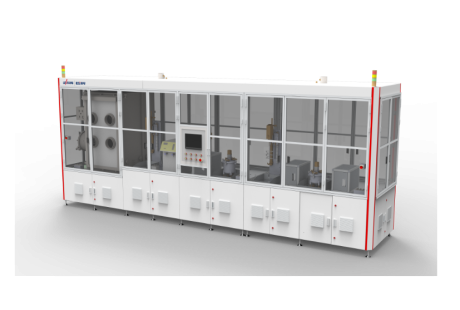

High Precision Mixing System

Suitable for fuel cell slurry automatic high precision mixing

Standard Configuration

Powder feeding

Powder metering

Liquid feeding

Liquid metering

Liquid pre-mixing

Powder liquid pre-mixing

Benefits of the Product

Powder liquid pre-mixing and vibration

Pure water making

Handling trolley

Raw material code scanning

MES

Technical Parameters

0.2~1.5g/cm³

1~500cp

±0.1g

2~1000g

2~3000g

20g/min (associated with powder density)

150g/min(associated with solvent density and viscosity)