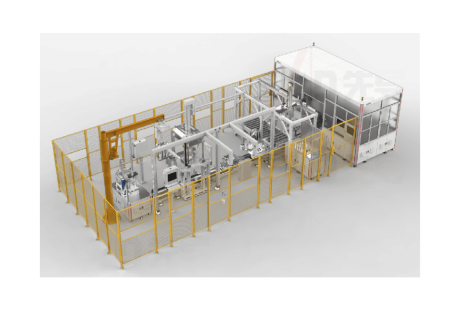

Equipment Advantages

Top speed and precision in the industry

This equipment is a highly automated device that integrates speed, precision, and accessibility. The single piece stacking cycle time (2.5s/PCS) and adjacent two piece stacking precision (± 0.1mm) represent the highest level in the industry, and it has good product compatibility and capacity scalability;

Integrated solution for stacking quality control system

integrating functional modules such as material posture holding, non-destructive flat picking, closed-loop detection throughout the entire process, non-contact online alignment detection, material size screening system, material splitting or paper separation system, etc., to form a complete stacking quality control system, ensuring stable and reliable stacking quality of the stack.