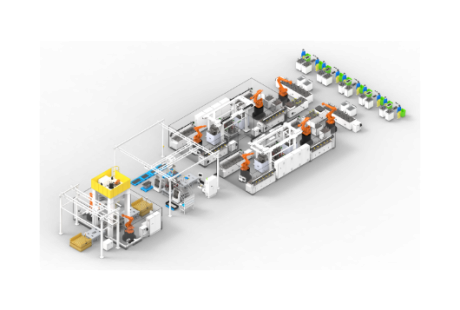

Assembly Plan for PEM Stack

The PEM electrolysis stack assembly production line equipped with gantry stacking, combined with the high-precision visual system. Functional units are set such as unpacking module, end plate assembly module, automatic pressing module, automatic tightening module, leak test module, and material transfer module. MES and intelligent logistics system are used, which can achieve intelligent production.

Key Features

LHI patented claws can pick up CCM and compatible of different materials with no damage

Closed-loop control to have high-speed and high-precision stacking

Rigid-frame servo hydraulic press has precise pressure and displacement control on the stack

2 screwing solutions can be applied: torque shaft or hydraulic tensioner

Pressure holding method and flow rate method can be used for high-pressure leak test of single gas or mixed gas

Standard Configuration

End plate assembly

Automatic stacking

Automatic pressing

Automatic tightening

Leak test

Offline module

Logistics

MES

Benefits of the Product

Automatic end plate assembly

Unpacking module

Material cleaning

Material pre-processing

Material pre-assembly

Technical Parameters

Item

Parameter

cycle time

8s/pcs

Stacking accuracy

± 0.25mm

Production capacity of

2000MW/year