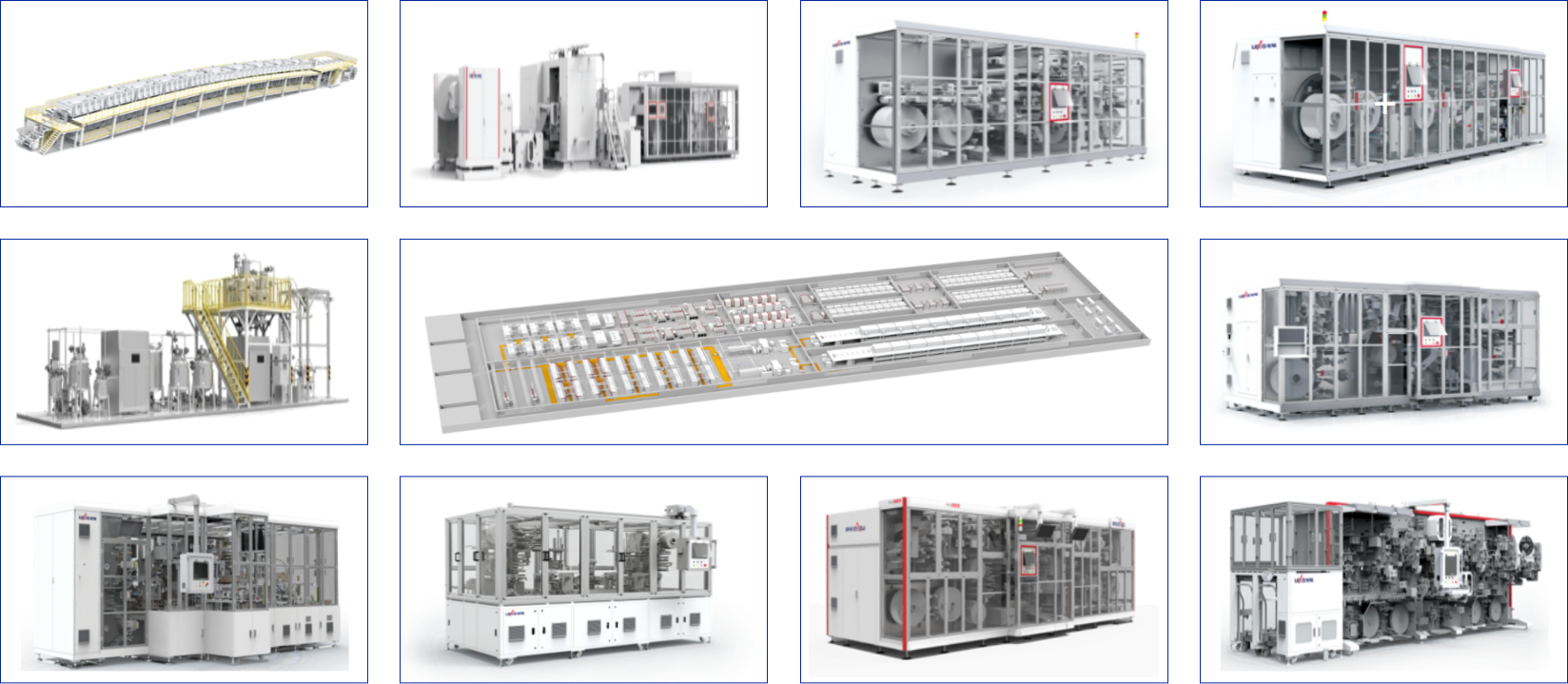

LEAD's Energy Storage LIB Manufacturing Turnkey Solution

In the field of energy storage equipment, LEAD has maintained its leadership in market share and has successively signed whole line orders withthe top 3 clean energy service providers in the industry. This helps reduce the ROl of batteries per GWh thus assisting customers in reducing costsand increasing efficiency. LEAD's energy storage LlB turnkey solution covers the whole line including machines for cell manufacturing, cellassembly, celltesting, and modulePACk. The line is equipped with LEAD's independently developed MES, inteligent logistics, and warehousing system. The aim is to providecustomers with a turnkey solution with higher capacity, lower energy consumption, higher OEE and yield rate.

Program value

Providing Energy Storage Turnkey Solutions

LEAD has undertaken more than 90 orders for cell manufacturing whole lines, and can provide customers with stable and efficient equipment and services at all sections in LIB manufacturing.

Leading the Industry in Whole-line Availability

The line has excellent cycle time and yield rate.

Higher Efficiency

The energy storage battery single-line efficiency reaches 30PPM.

Advantages of the plan

LEAD LIB Turnkey Solution

The prismatic cell mainly uses winded JR, with the mainstream model being 280Ah cell, and showing the trend toward large capacity cell, such as the 530Ah winded cell (73*275*209, equivalent to adding 100mm width to the 280Ah cell).