New Battery Module, Pack & CTP Manufacturing Equipment Turnkey Solution

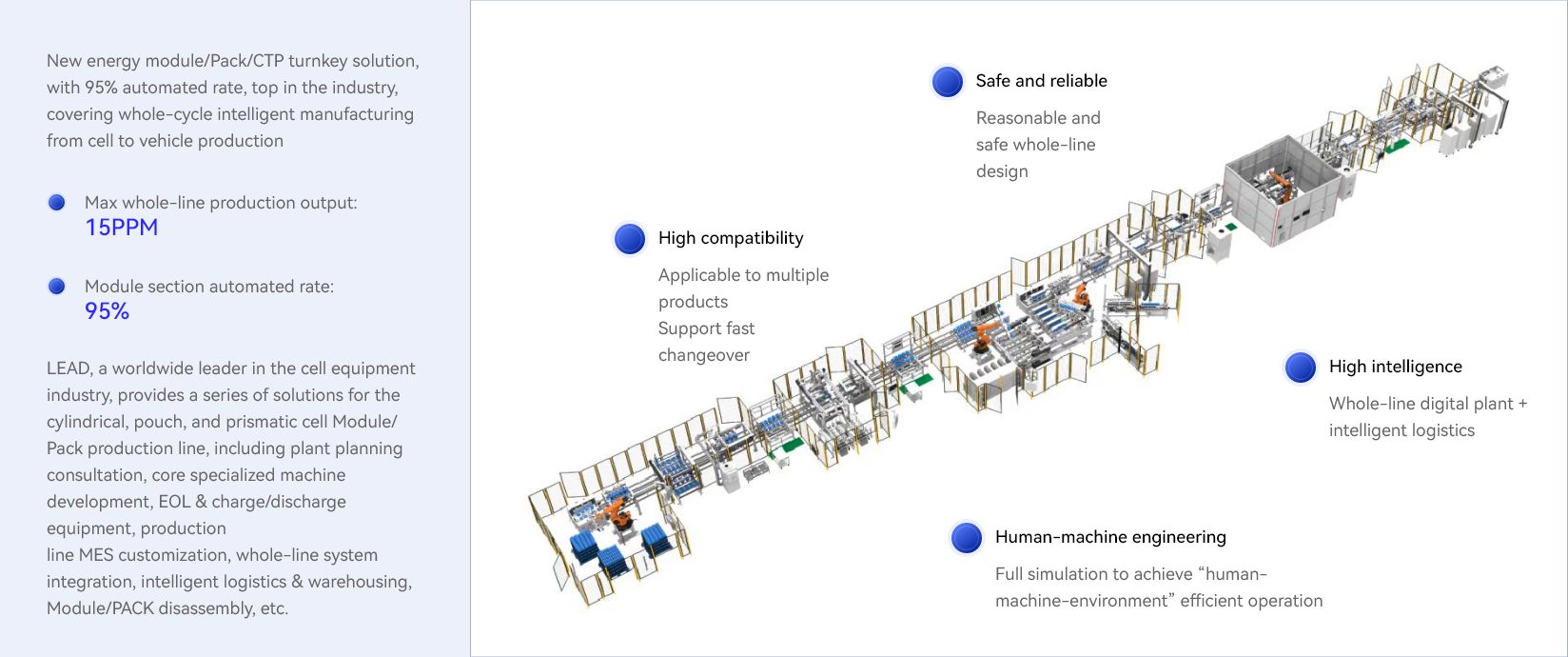

Relying on its global leadership in the battery equipment field, LEAD provides a series of solutions for cylindrical, pouch, prismatic cell module and PACK production lines. These solutions include factory planning consultation, core machine development, EOL & charge-discharge equipment self-production, production line MES customization, whole line system integration, intelligent logistics warehousing, module/PACK disassembly, etc. The automation rate reaches up to 95%, leading the industry and achieving intelligent manufacturing throughout the entire cycle from battery to automobile.

Program value

High Efficiency and High Automation of the Whole Line

The maximum efficiency of the whole line can reach 15PPM, with a high automation rate of 95% in the module section.

Seamless Integration of Battery to Automobile Intelligent Manufacturing throughout the Entire Lifecycle

LEAD provides new energy module/Pack/CTP turnkey solutions including cylindrical, pouch, and prismatic module and PACK production lines.

High Intelligence in Whole Line

The whole line combines digital factory and intelligent logistics, achieving efficient operation of “human-machine-environment” through full simulation.

Advantages of the plan

New Energy Module/Pack/CTP Turnkey Solution