LEAD's Cell Manufacturing Rear Section Turnkey Solution

As a global leader in formation and grading solutions, LEAD focuses on power electronics technology and temperature control technology, with a focus on formation & grading and inspection. LEAD’s formation and grading intelligent manufacturing turnkey solution integrates high-performance testing, advanced software development, and multi-dimensional simulation of system performance. By optimizing the formation and grading process, the solution leverages the high precision and consistency of the turnkey solution to address the problems such as high construction costs, high energy consumption, and unstable equipment quality in the formation and grading production line.

Program value

High energy feedback efficiency

reducing energy waste and lowering production costs.

High precision and high consistency

ensuring stable battery performance and improving overall battery pack performance.

Intelligent and automated design

with minimal or no human intervention, significantly reducing labor costs and the impact of manual operations on production.

Advantages of the plan

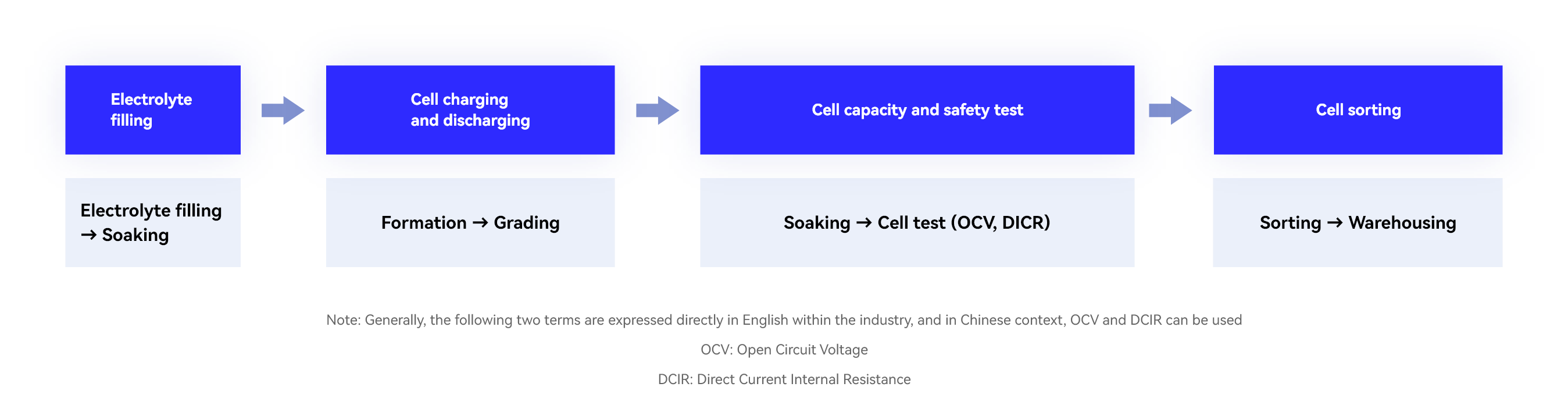

Cell Formation & Grading Solution--General Process Flow

Cell Testing Turnkey Solution