LEAD's intelligent high-efficiency TOPCon cell factory

Lead can provide customers with the turnkey solution of whole Topcon cell manufacturing line. The production line adopts the independently developed equipment by Lead, including the main cleaning and texturing equipment, main alkaline polishing and etching equipment, main polysiliconcleaning equipment, complete screen printing line, testing & sorting equipment, all automatic loading & unloading equipment through the whole production line, as well as unmanned AGV that connects all processes. The production line is equipped with industrial Internet digital solutions,achieving inline quality inspection, real-time data collection, information integration through the MES, to improve cell production yield, and realize thefull life cycle traceability of PV cells.

Advantages of the plan

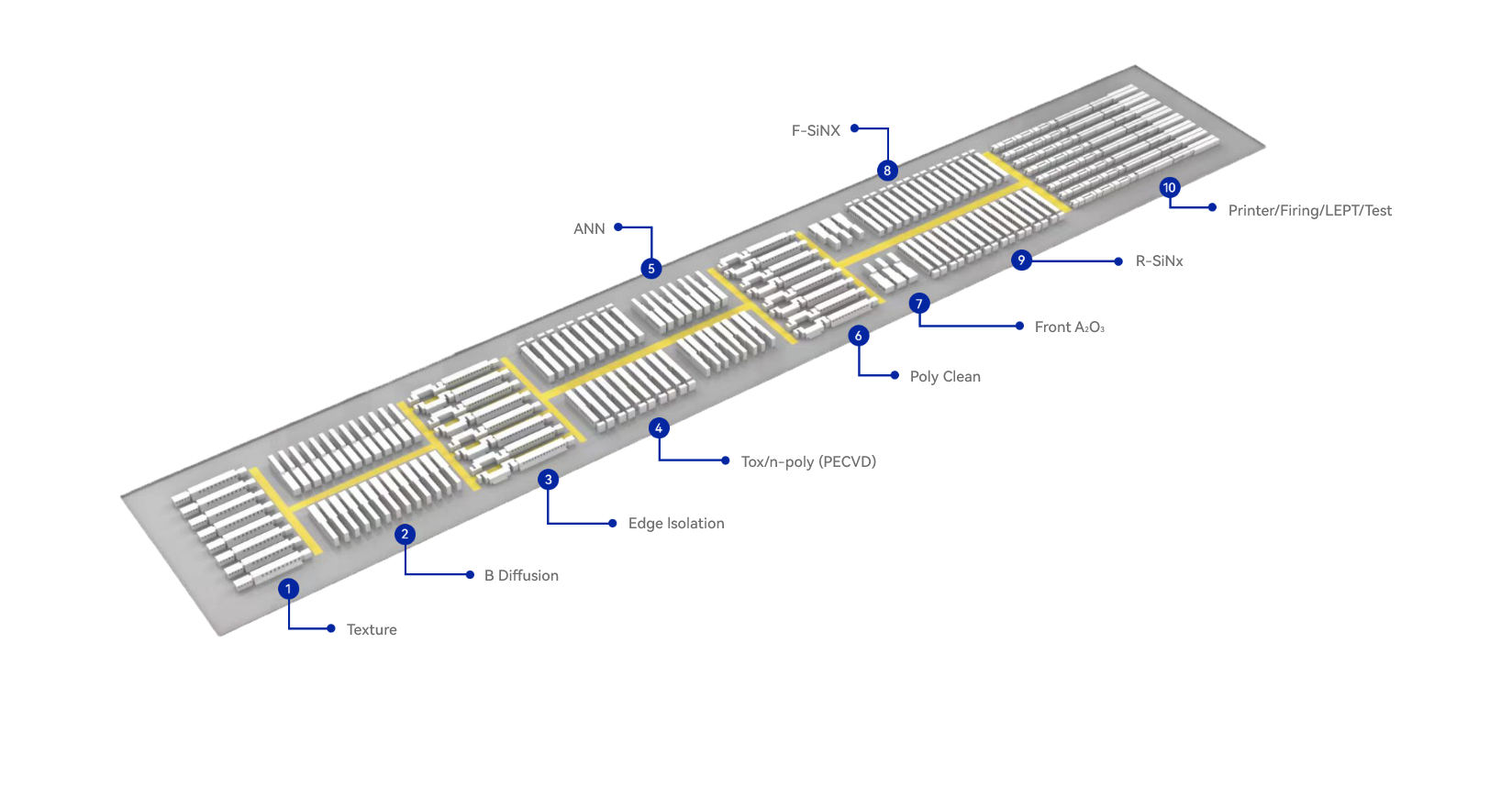

Topcon Photovoltaic Cell Whole Line Process