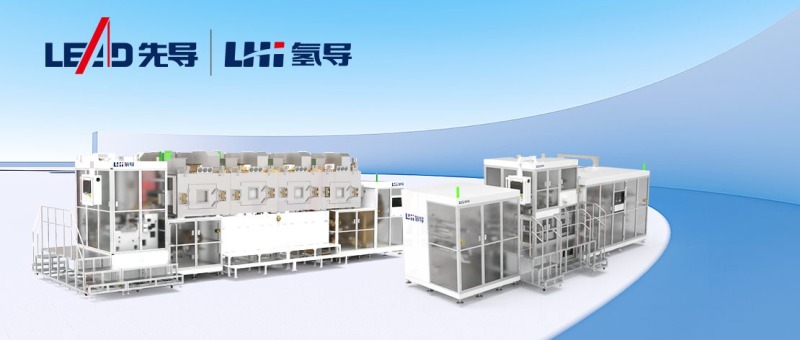

Recently, the Jiangsu Provincial Department of Industry and Information Technology officially announced the “2024 Jiangsu Province First (Set) Major Equipment List.” The high-end MEA coater, “LHCCM480CA/A Hydrogen Fuel Cell Membrane Electrode Precision Coating Complete Equipment,” independently developed by LHI, has successfully been included, marking a significant breakthrough for Lead Intelligent Equipment (hereafter referred to as LEAD) in the field of high-end hydrogen energy equipment manufacturing.

Multiple Key Process Breakthroughs Internationally Leading Technical Specifications

LEAD’s high-end MEA coater is designed for the high-precision, high-quality, and large-scale production of hydrogen fuel cell membrane electrodes, achieving breakthroughs in several internationally leading technical indicators. The thickness deviation of a single layer of catalyst is controlled within ±0.5μm, with a coating line speed of up to 5m/min, and the edge effect area of the equipment is maintained at ≤2mm. These technical parameters represent industry-leading standards and are prerequisites for the mass production of high-performance membrane electrodes.

By incorporating a highly adaptable controllable coating head and a robust slurry system, LEAD’s high-end MEA coater effectively mitigates disturbances during the coating process, ensuring the stability of slurry supply. Additionally, the equipment combines advanced tension control technology, achieving a tension control accuracy of ±1N, which guarantees both coating quality and production efficiency. These technological breakthroughs provide robust support for the sustainable development of the hydrogen energy industry.

Filling Industry Gaps and Providing Domestic Substitution of Core Equipment

The successful development of the high-end MEA coater fills a domestic gap in high-end hydrogen fuel cell equipment. In the past, China relied on imported equipment in this field, limiting the industry’s autonomous development and technological progress. Now, LEAD’s MEA coater not only possesses internationally leading technological capabilities but also offers a reliable domestic alternative for Chinese hydrogen energy and fuel enterprises, breaking the long-standing situation where the manufacturing of hydrogen fuel cell membrane electrode products was constrained by external factors, and promoting the industrialization of hydrogen energy and fuel cells in China.

Currently, LEAD’s MEA coater has completed the domestic substitution of membrane electrode direct coating equipment, effectively addressing the problems in membrane electrode production. It can also be directly applied to the preparation of core materials in PEM electrolyzers, flow batteries, and other industries. Moreover, the technological advancements of this equipment can drive key technological development in sectors such as semiconductors, optical films, and displays, thus promoting the upgrade of the entire high-end equipment manufacturing industry.

Stimulating Market Vitality and Leading a New Era in the Hydrogen Energy Industry

With the rapid growth of the global hydrogen fuel cell market, leading membrane electrode companies are launching large-scale expansion plans. In this context, LEAD’s capacity for domestic equipment substitution will bring significant economic benefits to the entire industry.

The equipment produced by LEAD not only effectively promotes a reduction in the equipment costs of the hydrogen fuel cell and electrolysis hydrogen production industries, helping membrane electrode companies lower production costs and enhance overall market competitiveness from the source, but also strengthens the stability of the hydrogen energy industry chain with domestically produced core equipment, enhancing China’s position in the international hydrogen energy sector and ensuring the safe development of the hydrogen industry. Currently, this high-end MEA coater is already being used by multiple domestic and international clients, and has received bulk production orders.

Looking ahead, LEAD will continue to drive the development of the hydrogen energy industry through innovation, advance technological progress in the hydrogen fuel cell sector, and contribute to the global zero-carbon goal. Through technological breakthroughs and industry collaboration, LEAD aims to establish a more comprehensive ecosystem for new energy equipment and contribute to the transition to sustainable energy, working alongside upstream and downstream partners to create a greener, low-carbon world.