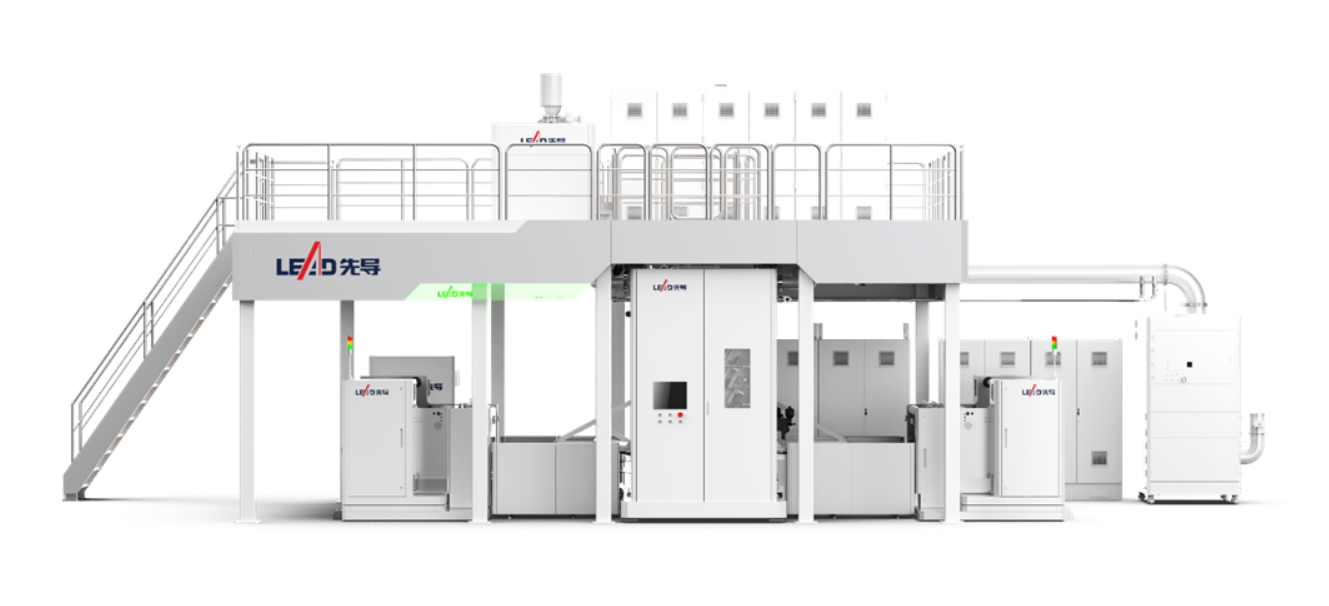

LHi, the subsidiary of LEAD, has successfully entered into the trial production phase after only four months of undertaking the whole line of fuel cell stack project, setting a new record for the highest speed of production line delivery.

The production line is the innovative result of in-depth communication and cooperation between the two parties. The stacking tact of the production line reaches 4s/pcs, and guarantees the high precision and consistency of stacking, which represents the highest technical level in the field of hydrogen fuel stack manufacturing.

With its technical background and professional accumulation of intelligent manufacturing in the field of fuel cell stack, LHi has helped the customer to comprehensively improve the automation level of production line. In this cooperation, LHi created the first automatic all-in-one can stacking and packaging system in China, helping the customer to realize the automatic stacking and packaging of high-power stacks, and providing support for its further expansion of production.

At the beginning of the project, LHi quickly set up a professional team to ensure the customer’s verification plan. With mature technology and strong supply chain system, LHi completed equipment acceptance and shipment within three months after winning the bid, and completed the first qualified product offline in only one month after factory commissioning, fully demonstrating its strong delivery capability as an industry leader.

It is not the first time for LHi to cooperate with SHPT. At present, LHi has established solid relationships with all the TOP customers in the field of hydrogen fuel cells. In the future, LHi will continue to lead the upgrade of hydrogen fuel equipment technology and contribute to accelerate the rapid development of the hydrogen fuel industry.