The appearance of smartphone directly impacts consumer purchase decisions and product reputation. As a result, manufacturers have very high precision requirements for smartphone appearance inspections, which must be fast and accurate. Lead Intelligent Equipment (hereafter referred to as LEAD), with its advanced equipment capabilities and cutting-edge inspection algorithms, has gained recognition from a leading smartphone manufacturer, providing a tailored appearance inspection mass production solution for high-end smartphones.

The client is a global leader in communication technology, operating in nearly 200 countries and regions, serving almost half of the global population. Its smartphone business holds a key industry position in both the global and Chinese smartphone markets, with top-tier technology and market performance.

Challenges in Smartphone Appearance Inspection: Low Efficiency and High Difficulty

As the largest external component of a smartphone, the smartphone shell not only affects the phone’s appearance and personalization but also plays a crucial role in its protection, durability, and user experience. Therefore, appearance inspection is a critical step in smartphone manufacturing.

Currently, smartphone shell inspection faces several key challenges:

- Complex and Varied Defects: Due to the structural uniqueness, various complex defects are often generated during the manufacturing process. These defects are diverse in type and characteristics, making the inspection process highly challenging.

- Poor Imaging: Due to the materials used, smartphone shells tend to reflect light and cause glare, making imaging unclear. Manufacturers require high precision and efficiency in appearance inspection to ensure production efficiency. The challenge lies in accurately and quickly identifying defects and providing timely feedback and resolution.

After multiple rounds of technical communication and comparative evaluation, LEAD’s solution, characterized by clear logic, advanced technology, and strict standards, was highly recognized by the client. LEAD was chosen as the supplier of appearance inspection equipment for smartphone frame and shell of the two high-end models.

Self-developed Inspection Platform and AI Algorithms Significantly Improve Inspection Efficiency

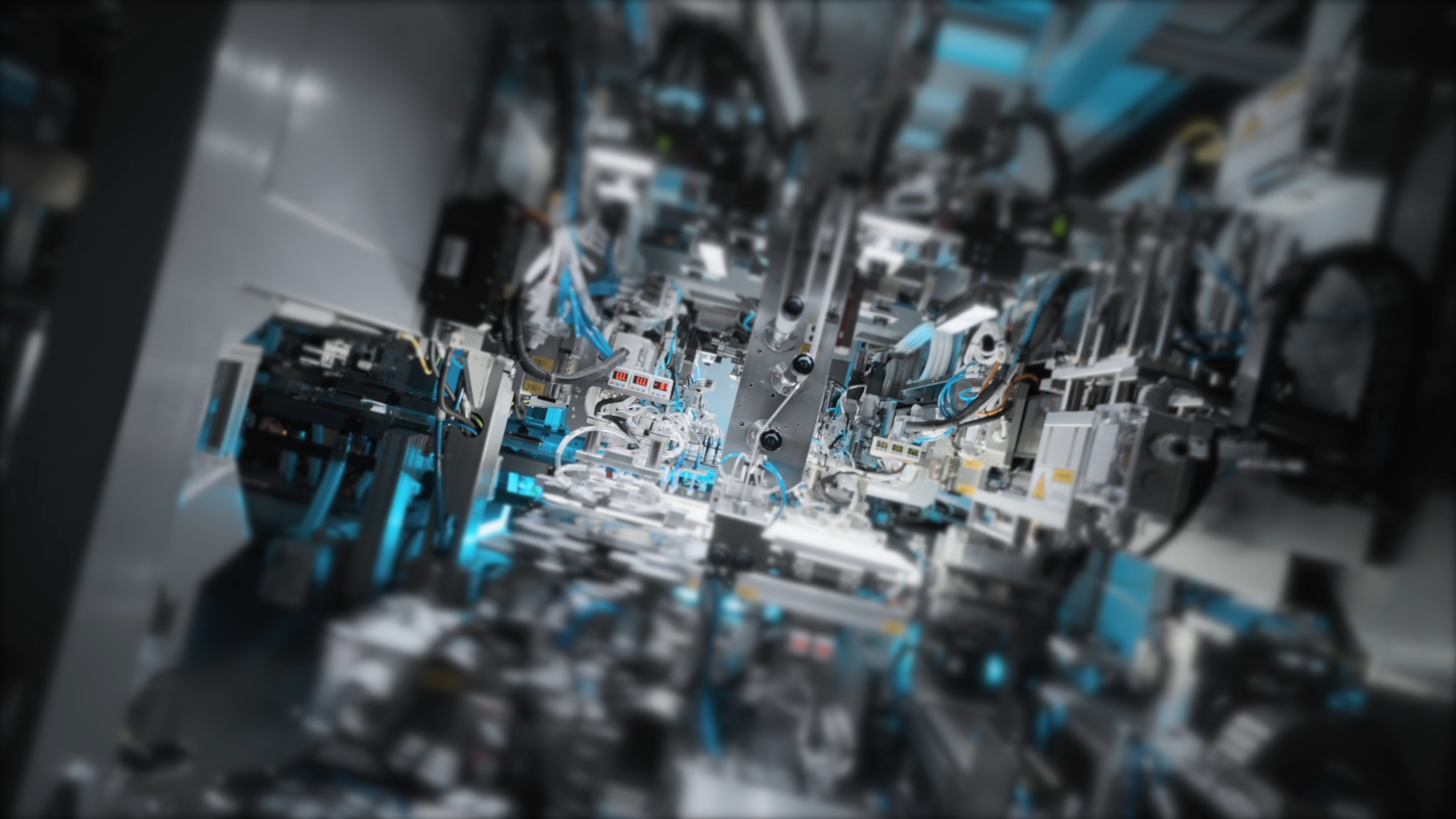

This project is LEAD’s significant AI-based flaw detection mass production project for 3C consumer electronics, combining traditional equipment advantages with LEAD’s self-developed algorithm expertise. The aim is to comprehensively verify and streamline processes, creating a high-end intelligent inspection platform to ensure full inspection before delivery.

Establishing a Project Collaboration Mechanism

After extensive preliminary communication and technical evaluations, LEAD’s team set up a targeted research and development coordination mechanism, quickly analyzing, diagnosing, and troubleshooting problems to enhance response speed and efficiency.

Technological Innovations of the Inspection Platform

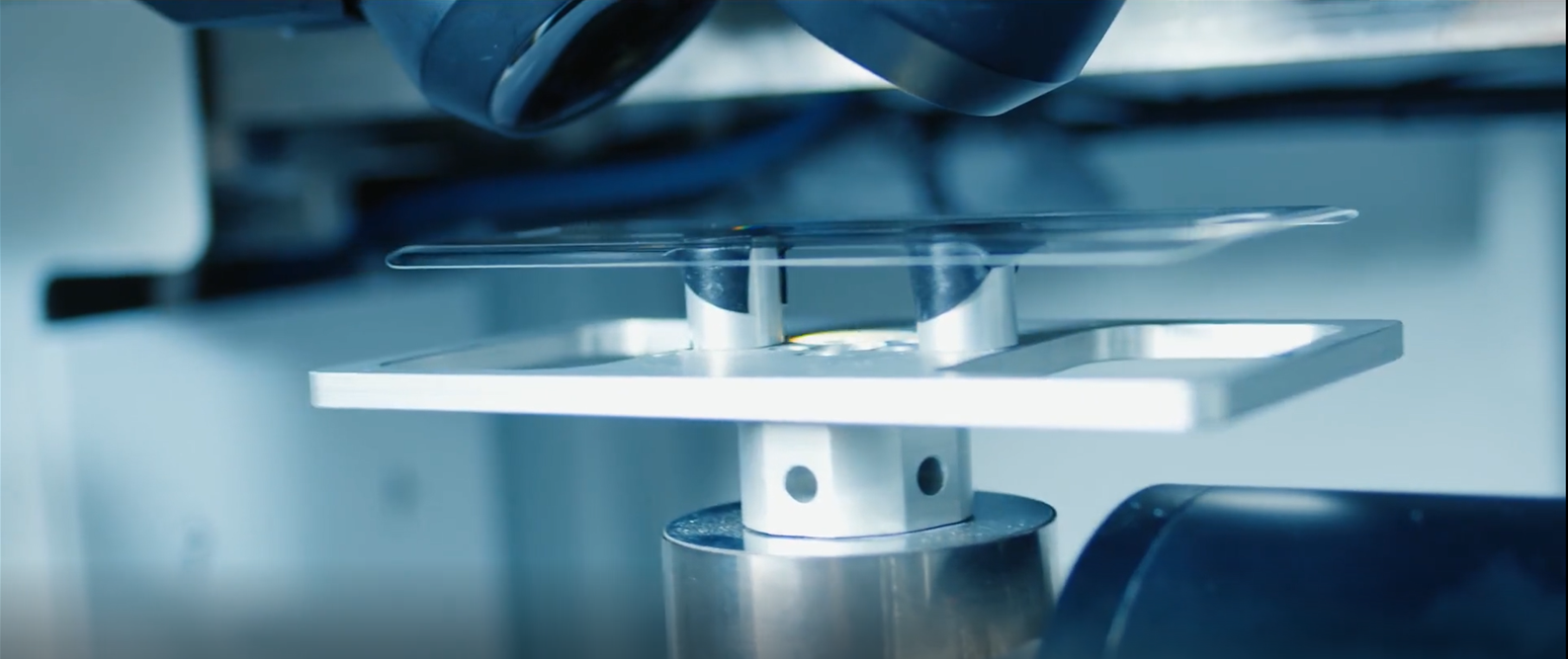

To address the complexity of smartphone shell structures, LEAD utilizes its patented inspection technology to automatically flip the objects by multiple angles and quickly image the products, enabling surface inspection of multi-layer products by directly measuring the smartphone shell’s morphological features.

High-Precision Image Capture and AI Algorithms

The high-precision, non-contact image capture technology enables real-time flaw identification, improving inspection efficiency and accuracy. Through LEAD’s self-developed 3D vision platform, feature identification is automatically performed. And with the integration of AI algorithms, the platform’s model training is reinforced, enabling the recognition and inspection of defects in various materials and curved surfaces.

With the support of equipment capabilities and 3D platform technology, this project successfully achieved the one-time acquisition of 140 detection data points, improving machine efficiency to 6 seconds per piece — more than ten times faster than traditional inspection methods and cutting labor costs by more than half. Furthermore, the AI platform’s defect sample calibration and analysis significantly boosted model training efficiency and detection capabilities. Enhanced post-processing algorithms and anomaly detection models accelerated model iterations and real-time upgrades of NG (No Good) assessment standards, adjusting tolerance ranges accordingly.

The final result of this intelligent appearance inspection solution achieved a defect miss rate of 0.5% and an overkill rate of 15%, significantly outperforming the industry average. The client highly recognized LEAD’s overall solution and expressed appreciation for the project’s success: “The LEAD team demonstrated strong technical expertise and exceptional project management capabilities. Their ability to quickly solve problems was particularly impressive. The team’s unwavering commitment and readiness to tackle challenges reflected LEAD’s service philosophy of ‘timely response and customer-first approach.’”

The manufacturing industry is undergoing a digital transformation driven by big data and cloud computing, as well as the development of industrial Internet technologies. Various sectors are actively seeking rapid and stable digital upgrades suited to their specific needs. AI technologies and digital management capabilities are independent of hardware manufacturing but are deeply rooted in a profound understanding of production equipment. LEAD integrates advanced technologies such as IoT, big data, AI, and edge computing to create an intelligent manufacturing system. This system, built from the client’s perspective, enhances operational efficiency, reduces costs, and helps enterprises transform into digital and smart factories by adopting standardized, efficient, and intelligent production methods.