LEAD's 46-series High-efficiency Automated Cylindrical Cell Intelligent Manufacturing Solution

By adopting a highly automated and intelligent production approach, the production efficiency, product quality, and consistency of the 46-series cylindrical cells are improved. The solution covers the entire production process, including raw material treatment, cell manufacturing, formation and grading, and module assembly, achieving efficient, precise, and reliable operation of the production line.

Program value

High automation rate

reducing labor costs and improving production efficiency and product consistency.

Precise control

achieving precise control and adjustment of production parameters.

Efficient production

focusing on energy saving, consumption reduction, and environmental protection during efficient production.

High quality assurance

strict control of production processes to ensure high-quality and stable products.

Advantages of the plan

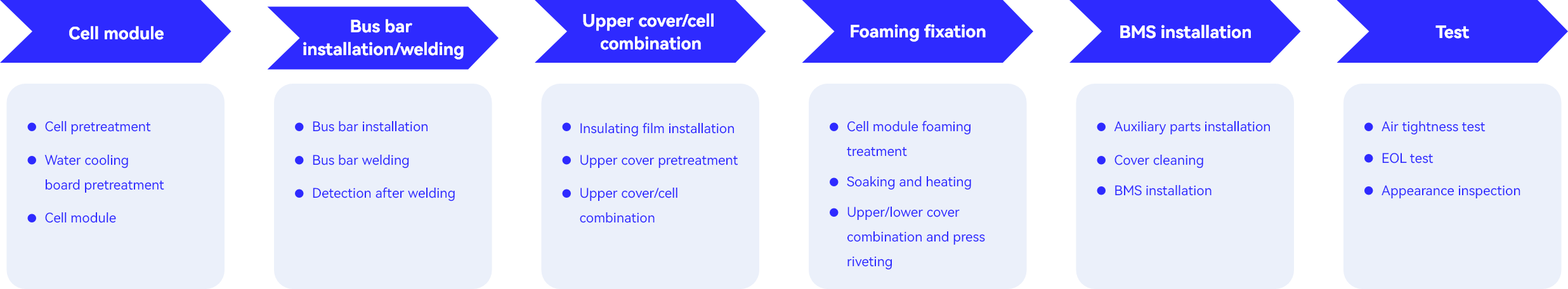

Process flow of 46 series cylindrical cell production line