LEAD's High-speed & High Charge/Discharge Rate Small Cylindrical Cell Assembly Line

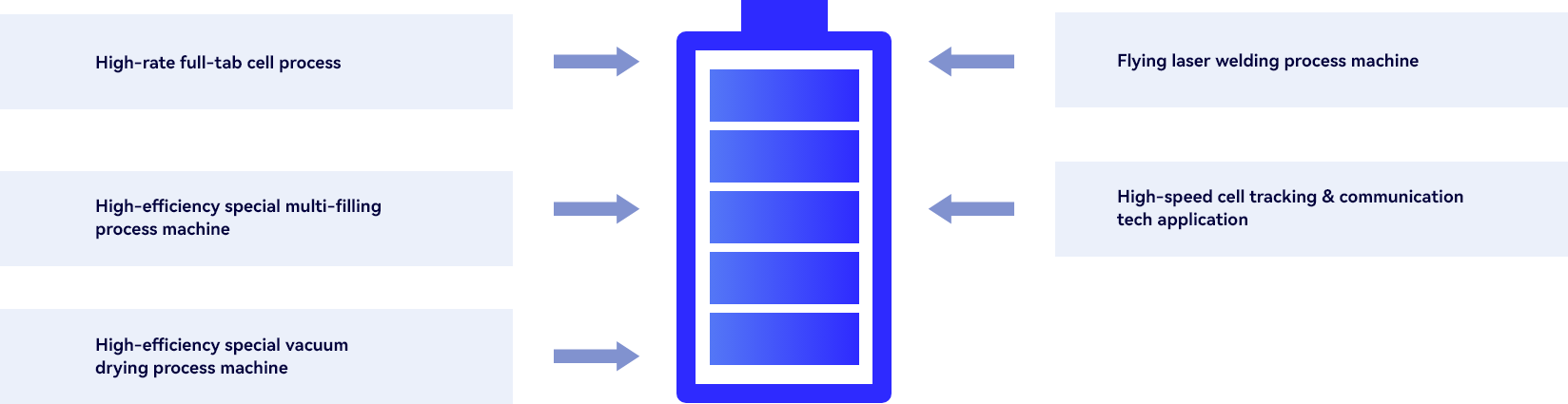

LEAD's hioh charge/discharge rate small cylindrical cell assembly line achieves an efficiency of up to 380PpM. The line is equipped with LEAD'Sadvanced high charge/discharge rate tab-less cell process,laser fily-welding technology, efficient and special multiple electrolyte filing proceshigh-speed cell traceability and communication technology application, as wellas efficient and special vacuum drying process. These technologiesgreatly enhance product stability, consistency, and yield rate. In terms of whole line operation, LEAD achieves the ful lifecycle management of small cylindrical cell manufacturing100% traceability is achieved for high-speed production of cylindrical cells,forming a complete traceability chain for personnel,machinery.materials,methods,and environment.

Program value

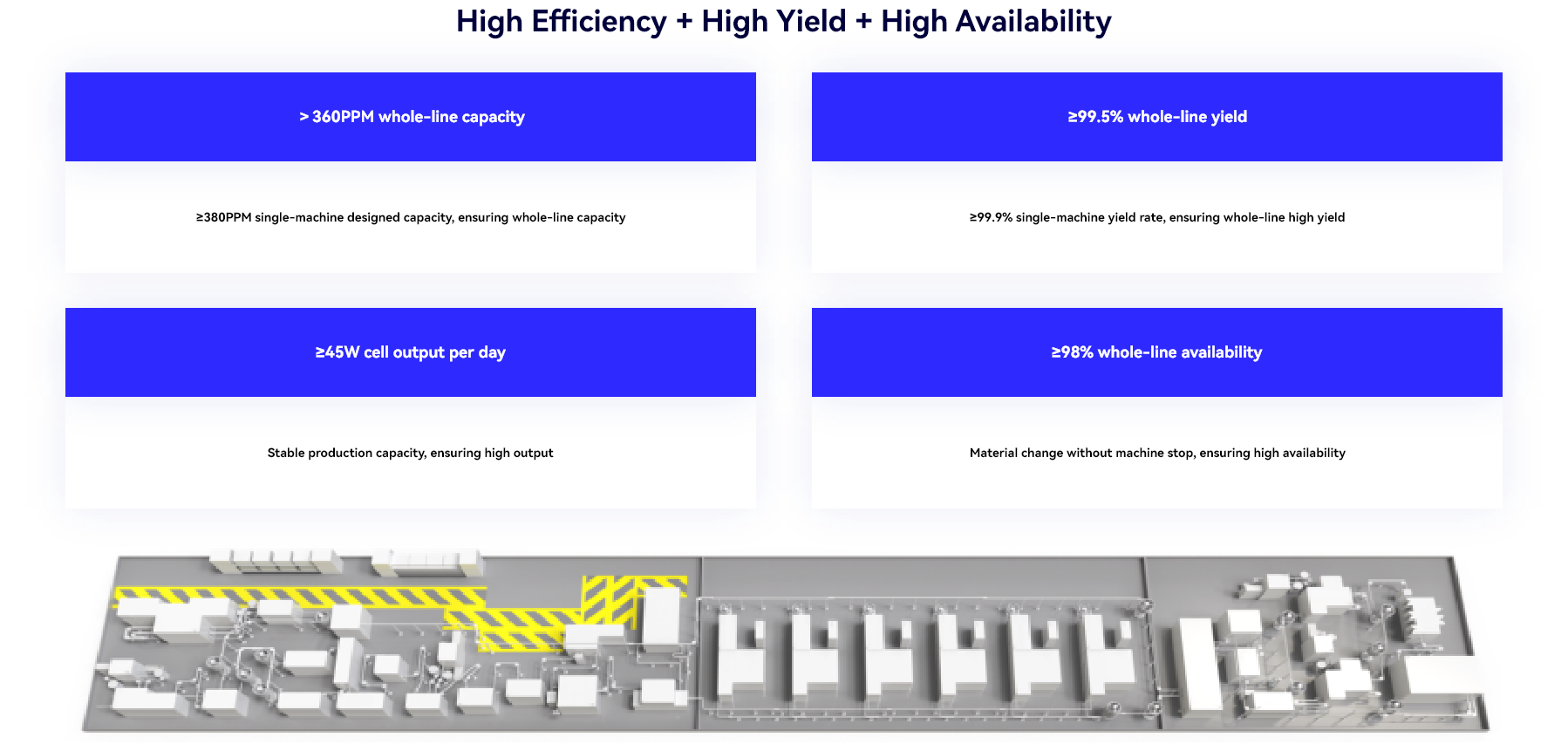

Capacity ≥ 380PPM

Leading the world in whole-line efficiency

High Yield Rate + High Availability

Whole-line comprehensive yield rate ≥ 99.5%, whole-line availability ≥ 98%

Laser Fly-welding Process

High efficiency + superior quality + low energy consumption cost + LWM full-process monitoring

Advantages of the plan

High Speed & High Rate – New Process Path

Case: LEAD Customer High-rate Cylindrical Cell 360 PPM Assembly Line