LEAD’s LIB Equipment Intelligent Operation Manager

How can we improve equipment MTBF and reduce operation and maintenance costs while ensuring the operation safety of the equipment? LEAD's independently developed inteligent operation and maintenance solution - the LlB Equipment inteligent 0peration & MaintenanceManager,is designed to be modular, allowing for comprehensive data collection and intearation with MES, ERP systems, and other informationsystems. lt helps to quickly build applications suitable for various scenarios in diferent industries, enabling real-time monitoring of equipmentoperation and maintenance status,reducing equipment response time to falure, improving equipment operation efficiency, Additionally. it can beintegrated with other systems to provide comprehensive production management decision-making support, enabling quick decision-making atthe management level and optimizing the entire lifecycle management of the production line.

Program value

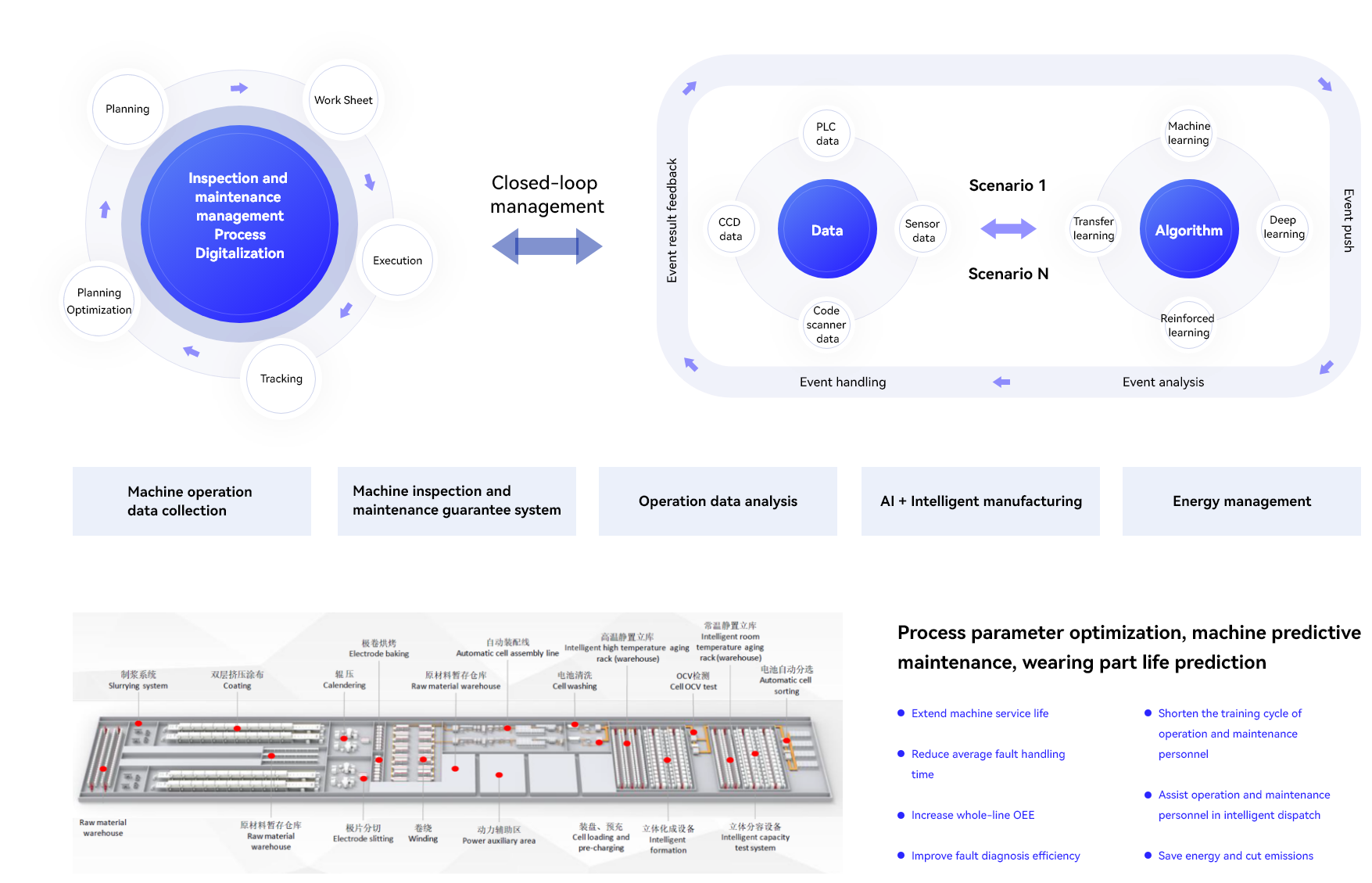

Closed-loop Process Management

Driven by both data and algorithms, achieving digitization and intelligence in equipment operation and maintenance.

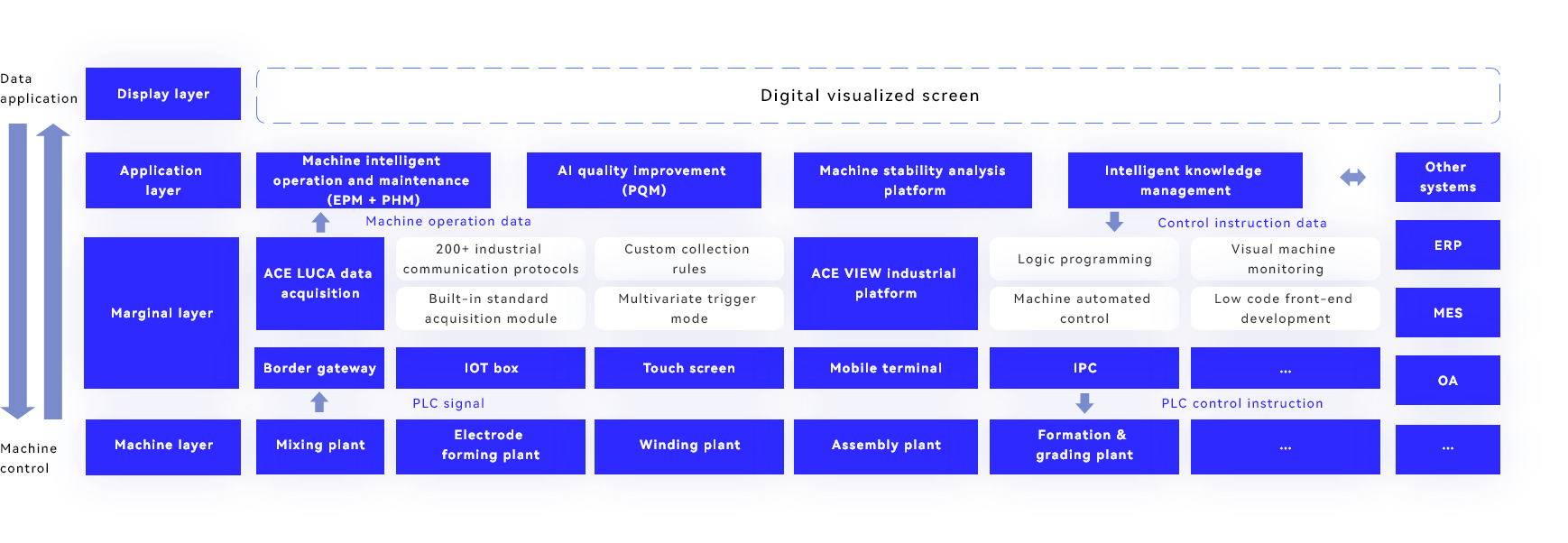

Integrated Cloud-edge-end Solution

Building an intelligent operation and maintenance platform (AIOps) to empower customers’ equipment operation and maintenance.

Centralized Display of Full Lifecycle Data

Providing clear visibility of equipment information throughout its entire lifecycle.

Advantages of the plan

Closed-loop process management, driven by data and algorithms, realizing digitalization and intelligence of machine operation and maintenance

Cloud-edge-end integration, building the Machine AI Operating System (AIOps) to empower customer in machine operation and maintenance