LEAD's New Energy Storage System Solution

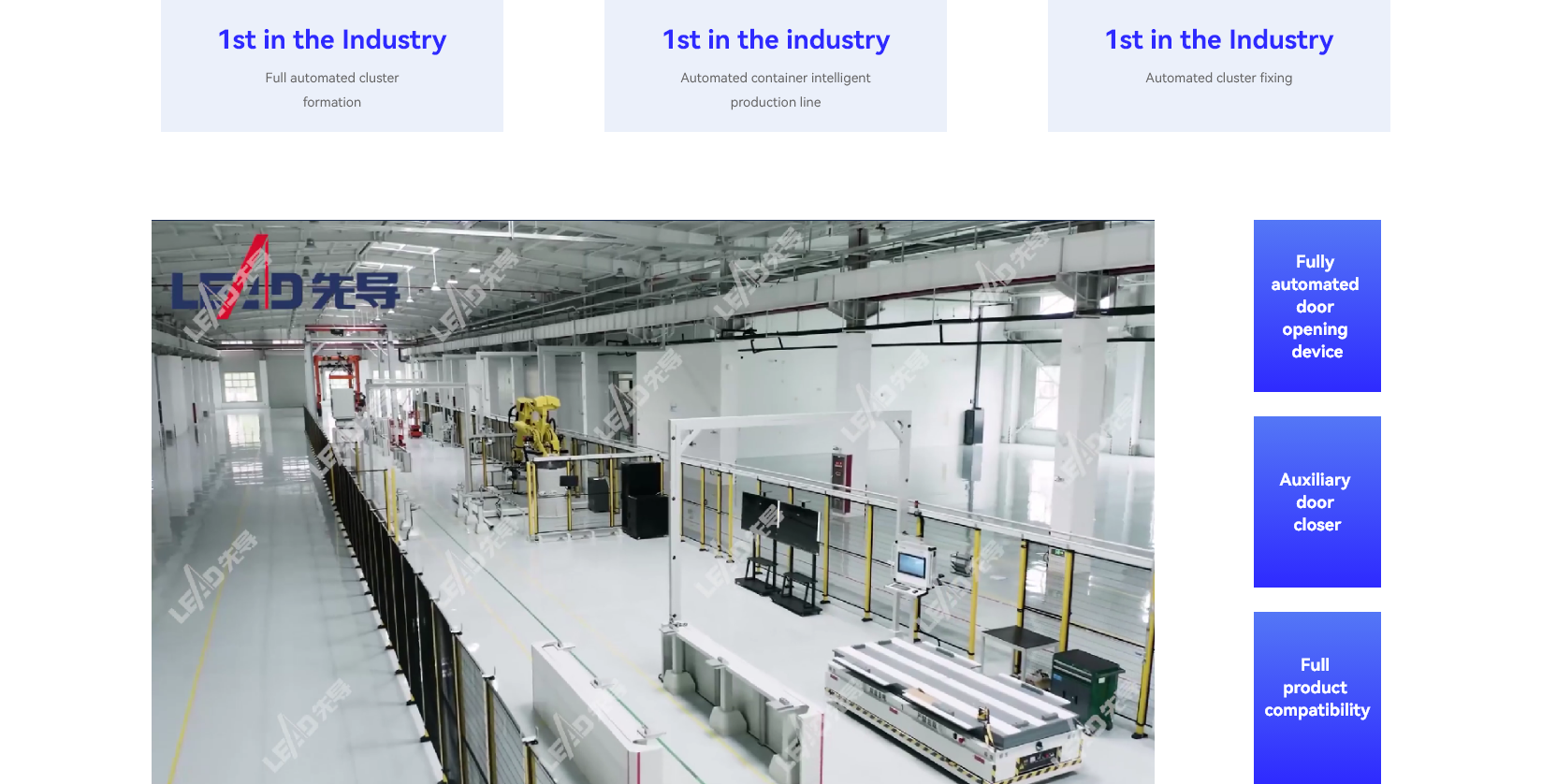

Energy storage container is considered a "must-have" for the future energy transition due to its high integration, large capacity, and mobility Upgrading from the traditional semi-automatic production mode, LEAD has pioneered the development of the industry's first fuly automatienergy storage container inteligent production line. The assembly automation rate has been increased to over 90%, with a product firt-time vielcrate of up to 95%. The overall production eficiency has improved by over 35%, with the battery consistency and stability also being greatly enhanced.

Program value

First in the Industry

Fully automated clustering of containers

First in the Industry

Automated container intelligent production line

First in the Industry

Automated tightening of clusters

LEAD New Energy Storage System

LEAD provides new energy storage system from module Pack to automated container,max 20GWh for single line.Fuly automated logistic,first in the industry toapply automated operation in high-intensity and high-risk stations! Energy storage container is considered to be a "must have" for future energy revolution due to its high integration,large capacity, and movablecharacteristics.LEAD took a big leap to forgo the conventional semi-automatic production mode and developed the 1st fuly automated energy storagecontainer inteligent ine of the industny. with the assembly automation rate exceeding 90%, first time vield rate reaching 95%,overll production eficiencyimproving by 35%+. In the meantime, the consistency and stability of cells are greatly enhanced.