New Energy Vehicles Comprehensive Testing Solution

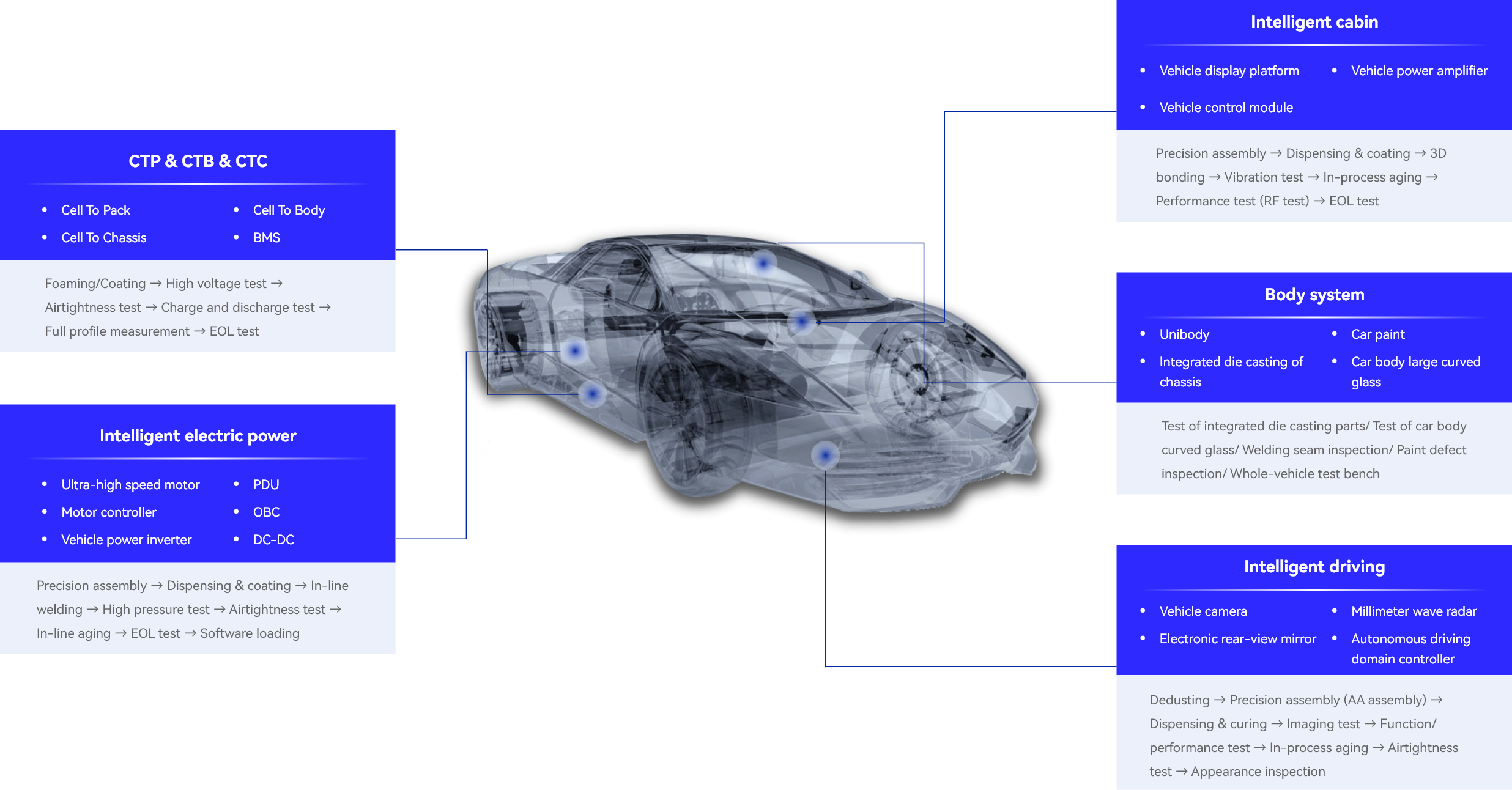

LEAD’s comprehensive testing solution for new energy vehicles covers multiple aspects from power systems to the entire vehicle, including but not limited to power system testing, power battery production line testing, motor performance testing, and vehicle communication testing. This solution assists in the comprehensive evaluation of various performance indicators of the vehicle by the OEMs, ensuring compliance with design requirements and market standards.

Program value

High precision and efficiency

Accurately capturing various performance indicators to ensure accurate and reliable test results.

Comprehensive coverage

Covering multiple key aspects and areas of the automotive industry to ensure a comprehensive evaluation of overall performance.

High intelligence and automation

Combining intelligent equipment and production lines, intelligent management and services to improve testing efficiency and accuracy, and reduce labor costs.

Data analysis and decision support

Deep mining and analysis of data to provide valuable decision support information for enterprises.

Advantages of the plan

Focus on the new energy vehicle industry