Key Features

Resource optimization: We ensure that every resource is utilized most efficiently on the production line through precise demand analysis and process design. This not only reduces material waste, but also lowers energy consumption, achieving cost optimization.

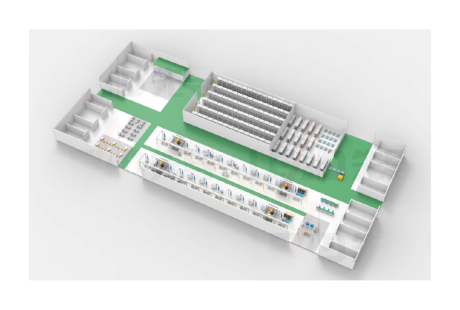

Production efficiency improvement: Reasonable workstation layout and operation process design have significantly improved production efficiency. Employees have the shortest movement path during task execution, reducing ineffective work and time loss, thereby accelerating the entire process of product assembly to testing.

Product quality assurance: A complete quality control system runs through the entire production process, from the input of raw materials to the output of the final product, with strict quality checks at every step to ensure consistency and reliability of product quality.

Technological innovation: We constantly explore and apply the latest technologies, such as automation, robotics, and the Internet of Things, to improve the automation and intelligence level of our production lines. The application of these advanced technologies not only improves production efficiency, but also enhances product accuracy and consistency.