Key Features

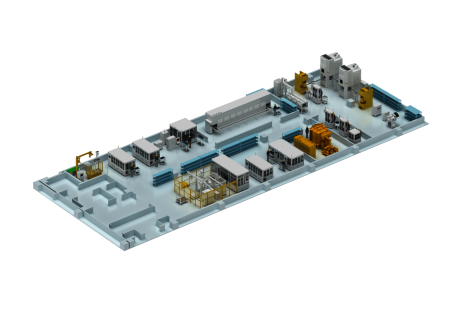

using two-stage stamping technology to reduce product warpage and achieve high yield of plate stamping;

Using virtual simulation to simulate the formability of lates and provide positive guidance for product design;

Using ultrasonic water-based cleaning for plates, the cleaning equipment is compatible with unipolar and bipolar plates, and the quality of the cleaned polar plates meets the requirements of welding and coating;

By using laser galvanometer welding technology, protective gas welding can be achieved;

Adopting the sealing ring bonding process, the quality of the finished bipolar plate is fully inspected online;