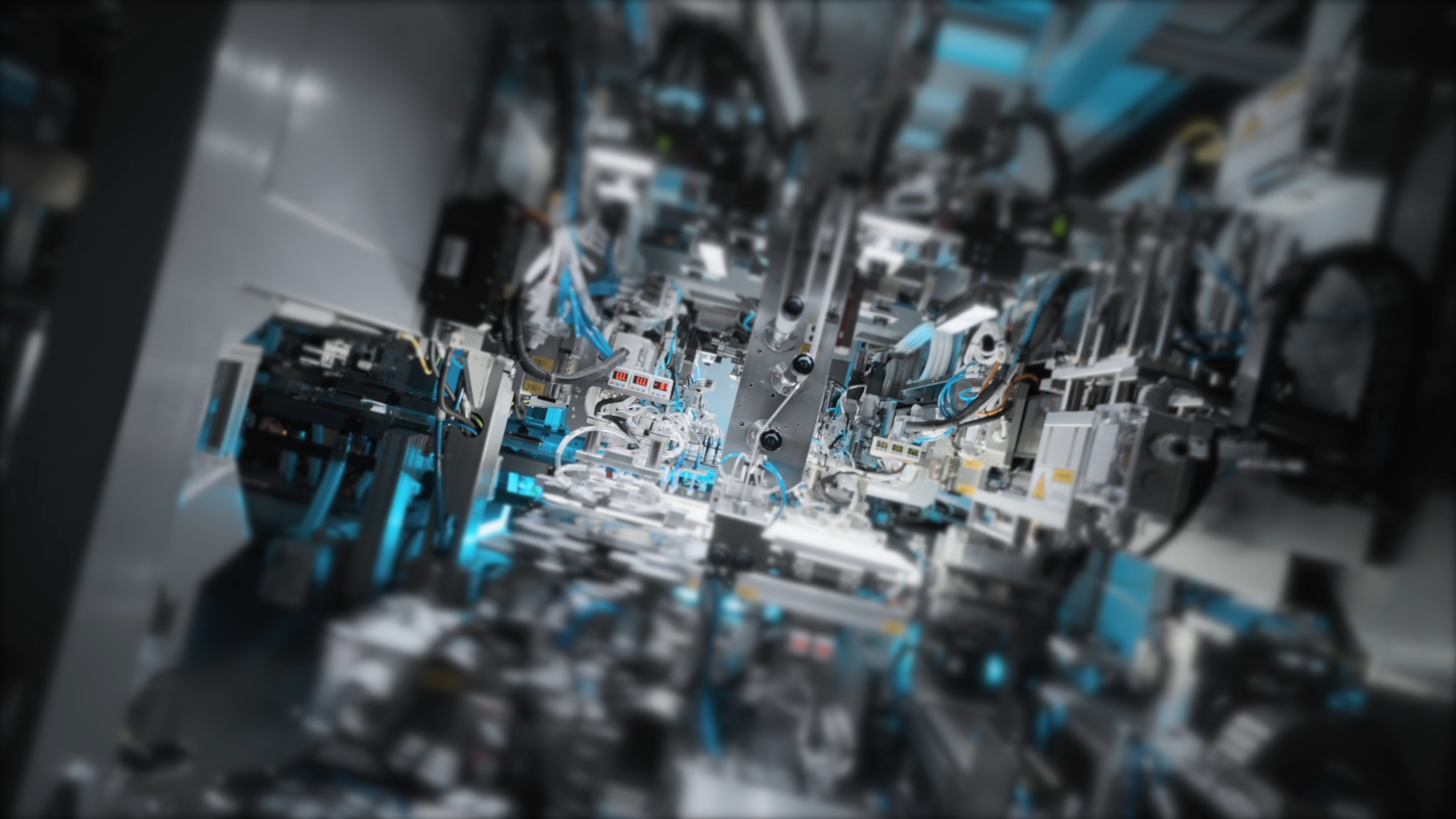

Formation and Aging Intelligent Manufacturing Turnkey Solutions for Cylindrical Cell

Cylindrical cell formation and aging production line adopts industry-leading integrated technology with PCS and water-cooling & water-heating, providing battery companies with a complete production line for large cylindrical lithium-ion cells including pre-charging, high-temperature aging, rotation, nail extraction, high-temperature formation, nail insertion, OCV testing, room-temperature aging, assembly line, capacity grading, DCIR testing, and sorting, as well as for small

cylindrical lithium-ion cells including pre-charging, high-temperature aging, formation, capacity grading, OCV testing, NG sorting, room-temperature aging, and sorting, along with intelligent logistics throughout the line, combined with self-developed FGS, BIMP, dedicated to building intelligent factories for battery companies.

Currently, we have established strategic partnerships with globally renowned battery manufacturers.