Turnkey Solutions for Fuel Cell Intelligent Manufacturing

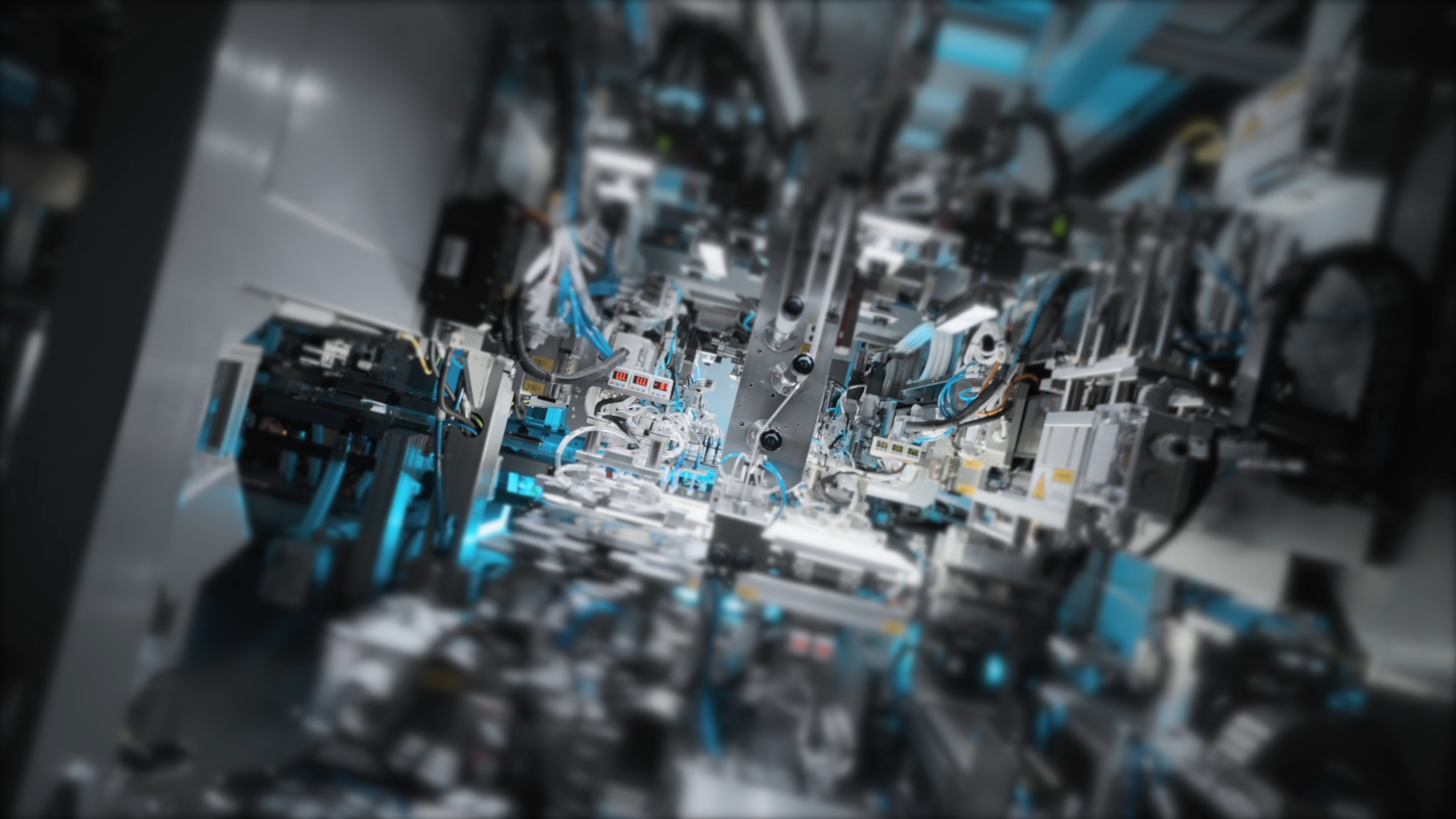

Jiangsu Hydrogen Conductive Intelligent Machine Co., Ltd., founded in 2021, is a wholly-owned subsidiary of Wuxi Pioneer Intelligent Machine Co., Ltd., which is committed to the overall solution of hydrogen fuel cell and PEM electrolytic cell production line, and strives to promote the global fuel cell industrialization process, including the upstream material production line – PEM coating Machine, GDL production line, carbon paper production line; Production Machine – slurry coating, membrane electrode packaging, bipolar plate whole

line integration, stack assembly and system line; Test machine – high-power stack test platform, high-power system test platform, durability test bench, etc.

Relying on its strong R&D, manufacturing and comprehensive service capabilities, LHl is able to provide customers with production process validation and equipment for lab line, pilot line and production line, and has already provided automatic fuel cell production lines for well-known domestic and foreign customers.